Our shop accepts orders from professional organ builders only.

Please register for a customer account. Once we've verified your application and activate your account, all pricing information and functions will be available.

The registration form asks for a European VAT-number.

US customers please enter your EIN (Employer Identification Number).

If you have specific questions about our products don't hesitate to get in touch by email of phone.

The most intelligent slider magnet

All of your stops will move in perfect sync.

Now even easier to operate

with a display of the actual operating current.

The organ is a musical instrument, not a giant switchboard.

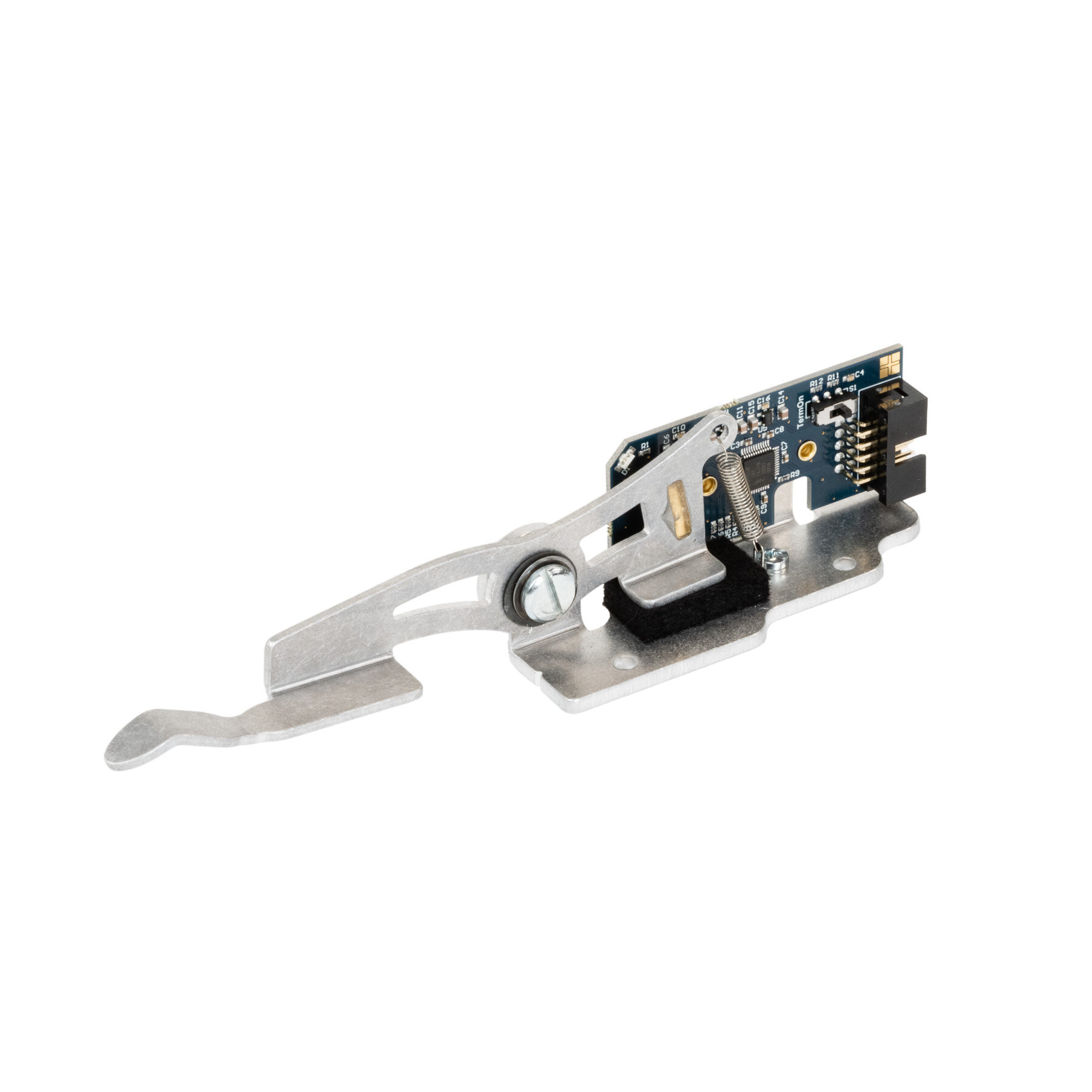

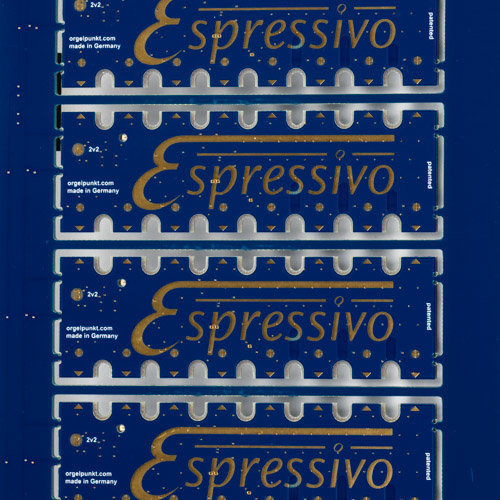

More musicality in electric actions: This was the core idea behind the first development of orgelpunkt.com - the revolutionary Espressivo keyboard system. Continuous detection of the key position with wear-free magnetic sensors opens up possibilities that no other contact offers, whether classic wire fingers or more modern opto contacts. All of these contacts have only one position at which they switch, and mechanical regulation, especially on multi-manual consoles, is hours of tinkering, usually resulting in half-baked compromises.

If the keyboard is equipped with Espressivo, each key can be adjusted at any time via tablet or laptop to an accuracy of a tenth of a millimeter. The patented switching point spread and 2-point repetition also allow the switch-off position to be set lower than the switch-on point. This eliminates the "doughy" feel that bothers many organists on conventional electric actions. And electric couplers can now be perfectly matched with mechanical actions.

Espressivo is the only action system that, thanks to its patented process with precise organ-typical pre-travel of the keys, simultaneously captures the expression of the playing and transmits it as MIDI velocity. This allows external sound generators, such as electronic pianos, which are being used more and more frequently in churches, to be connected to the organ play in a musically expressive way.

The counterpart to the key sensors is the windchest module, which, unlike other control systems, does not just rudely switch valve solenoids on and off, but uses dynamic valve control to actuate the solenoids with finely graduated voltage curves that depend on the speed of the keystroke.

Depending on the construction of the windchests and voicing of the stops, the dynamic control system allows subtle articulation, but above all a reduction in action noise. This is because where conventional control systems only know full throttle and hard braking, the dynamic control system adapts the current pulses of the magnets to the musical performance.

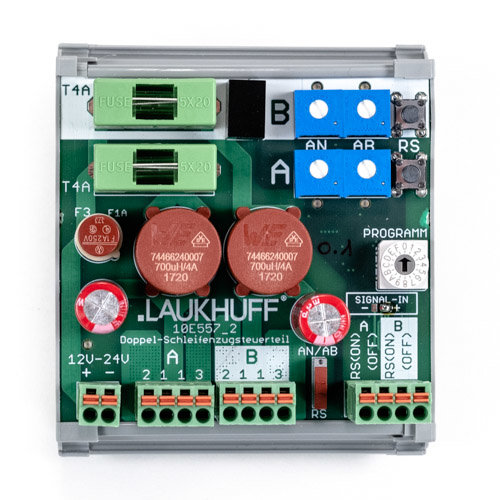

The dynamic control system works with all conventional action and valve solenoids, is comparable in price to normal PLC-based systems and, thanks to its modular design, significantly reduces the effort required for cabling and organ installation.

Above all, you can configure the modular key action completely by yourself. Even complex single note chests with many transmissions, extensions and additions can be designed on your own according to your musical concepts, without the detour via programmers and numerous updates - the ideal basis for exploring new concepts, as well as the simple solution for retrofitting existing instruments by directly connecting the keyboard and windchest systems.

Orgelpunkt is part of a network of highly qualified specialists who share a passion for organ building and sophisticated craftsmanship. FSB Orgelbau, Frankfurt, is one of the first Espressivo users. Here, decades of experience in the substance-preserving restoration of historic electropneumatics are combined with a profound passion for experimentation that produces percussion instruments that can be played with dynamic velocity, such as vibraphones and glockenspiels. Traditional cymbal stars are manufactured in the workshop as well as state-of-the-art organ power supplies in customized design.

The organ as a musical instrument, not as a technology playground, that is the central principle behind our developments. The intelligent S1.2 slider solenoid, for example, ensures that stops operate precisely, whatever the season. Sensors monitor every operation, and the electronics adjust the current at the slightest sign that humidity or temperature have made the sliders sluggish. So no stop misses its cue, and the organ builder doesn't have to rush in at the last minute before a concert to get a stuck stop working again.

Our slider solenoid always works with optimal power and defers to the music instead of stealing the limelight with its own percussion performance. There is no need for the most usual rumble that shakes the gallery in the silence before the fortissimo chord when the organist engages the tutti switch. The musicians give the command - the sliders glide almost silently into position.

We make no compromises in the choice of components. The electromagnets are supplied by the world market leader Kendrion, which was also a manufacturing partner of Aug. Laukhuff GmbH for decades. In the development of the electronics, we rely on the many years of experience of the Laukhuff developers and have circuit boards and subassemblies manufactured exclusively by ISO-certified companies.

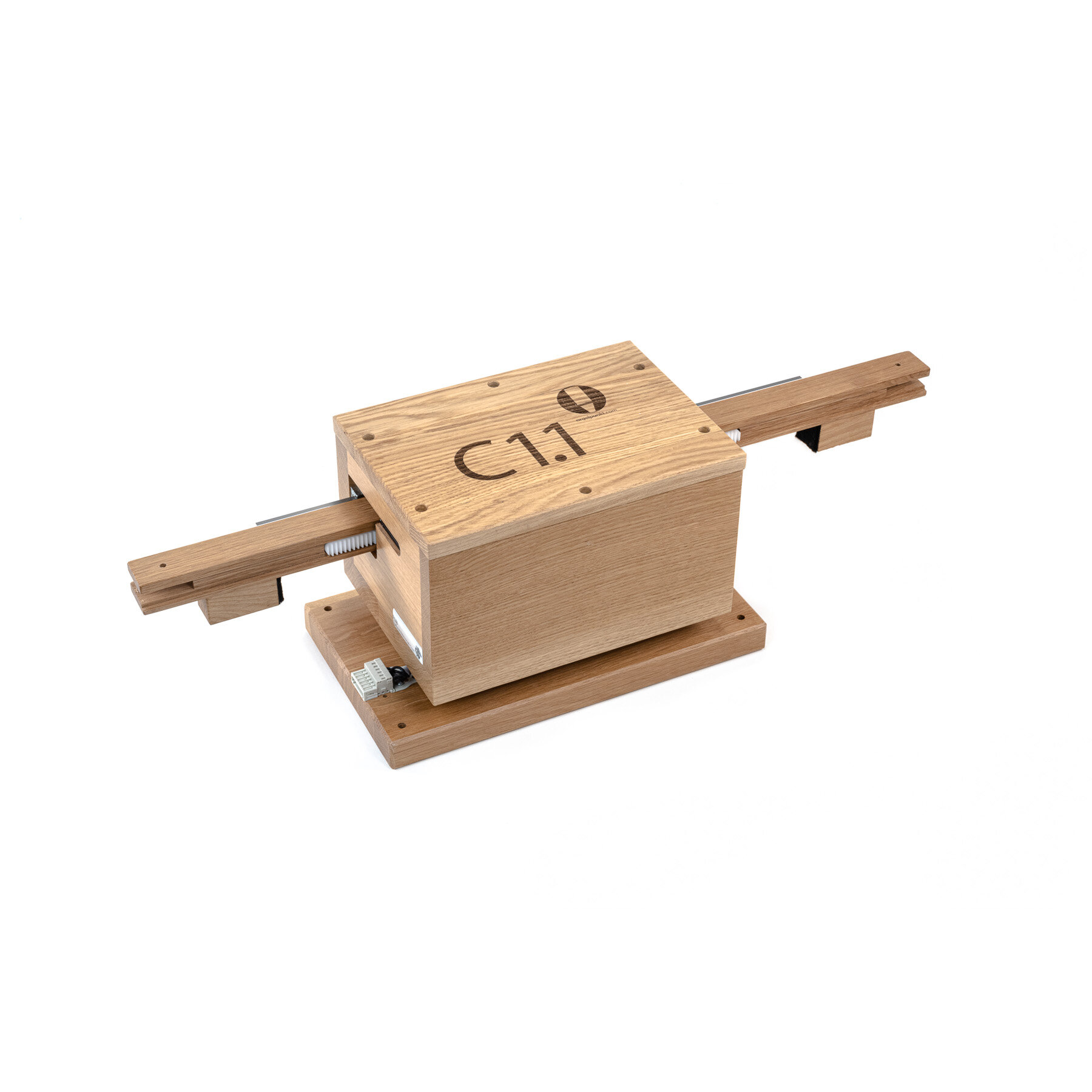

Our latest product is the swell control unit C1.1. Also in this electronics we are taking the next step, based on years of development know-how. A swell control unit must not only move heavy wooden parts precisely. What is crucial is the finely nuanced opening on the critical first few centimeters, when the swell shades begin to release the sound stream into the church space. Each swell division and each room has its own acoustic characteristics and individual musical effect.

The control unit therefore has a large graphic display on which you can precisely adjust the progression curve - the translation between the position of the swell pedal and the opening of the swell panel - to the instrument in 100 variations. The high signal resolution of 127 steps guarantees fine musical control at all times, even with steep progression curves.

The swell shades drive unit continues to be manufactured in the solid oak cabinet according to the proven original Laukhuff design. The engine's unrivaled quietness is legendary. Its wooden components can be adapted by organ builders to the individual requirements of the instrument with little effort.

All offered electrical and electronic components are intended for use in organ building. According to the exemptions from the RoHS regulations for organ building, the RoHS conformity of the offered components is not implied or guaranteed.

The components are intended exclusively for permanent installation by qualified personnel and do not fall under the scope of the WEEE-directives (German ElektroG to §2, para. 2).

They are not WEEE-registered, the professional disposal is the responsibility of the user.

The use of solder containing lead cannot be excluded, especially in the case of offered stocks of older components or spare parts for existing equipment.